Description

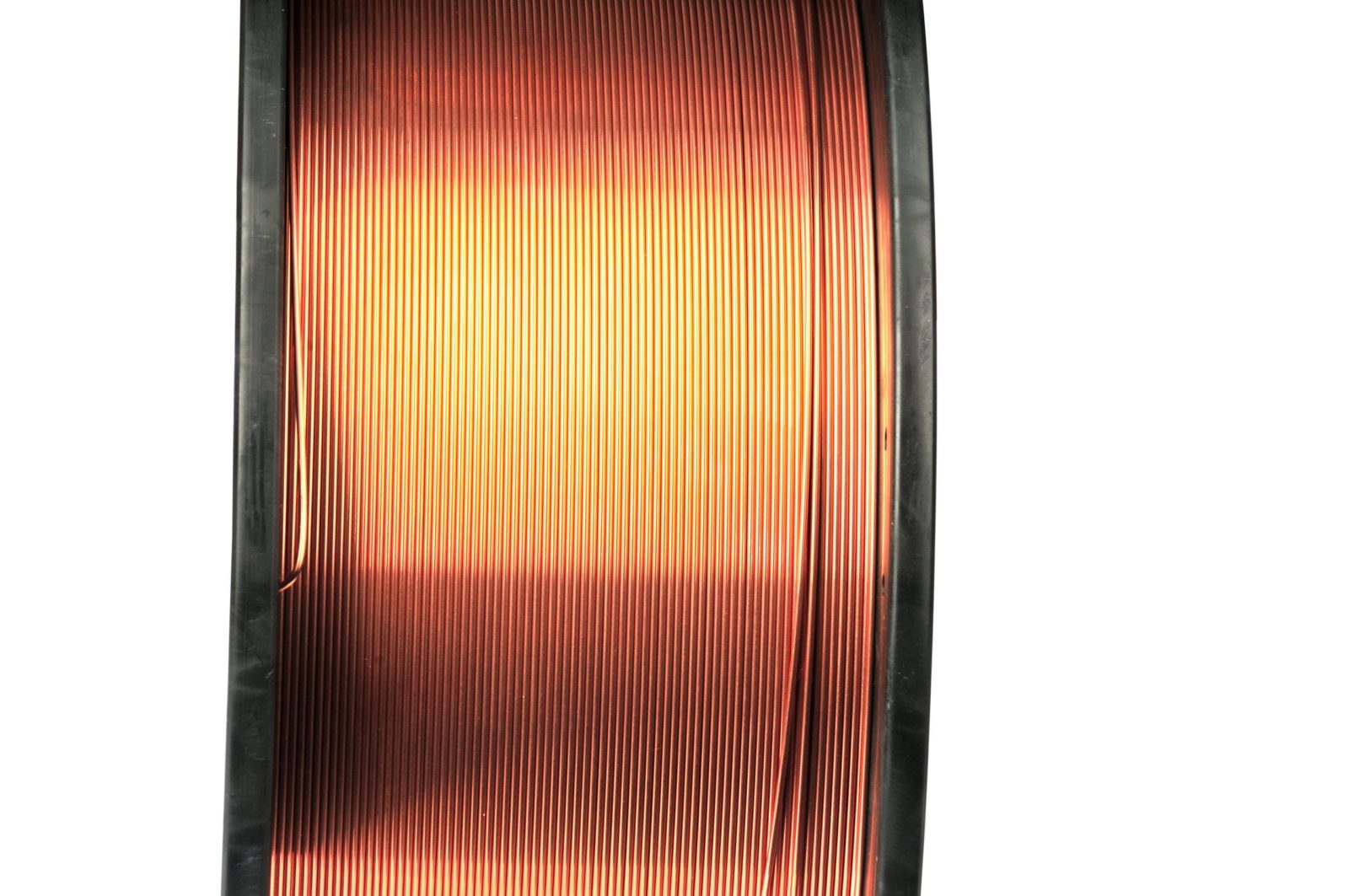

Welding copper-coated wire ER70S-6 is designed for semi-automatic and automatic welding and surfacing in carbon dioxide CO2 or gas mixture Ar+CO2. Used for welding of carbon and low-alloy structural steels, shipbuilding steels of normal and increased strength, steel forgings and castings of the corresponding strength categories as well as matching steels for the manufacture of ship structures and pressure vessels. For both single-pass and multi-pass welding (surfacing) in all spatial positions.

The main advantages of the welding wire are high-quality coppering, stable diameter over the entire length in combination with low content of harmful impurities, they ensure stable wire burning with minimum spattering.

Can be used at low temperatures. Precision layers winding ensures smooth feeding of the welding wire into welding area, eliminating its deformation and bending.