Description

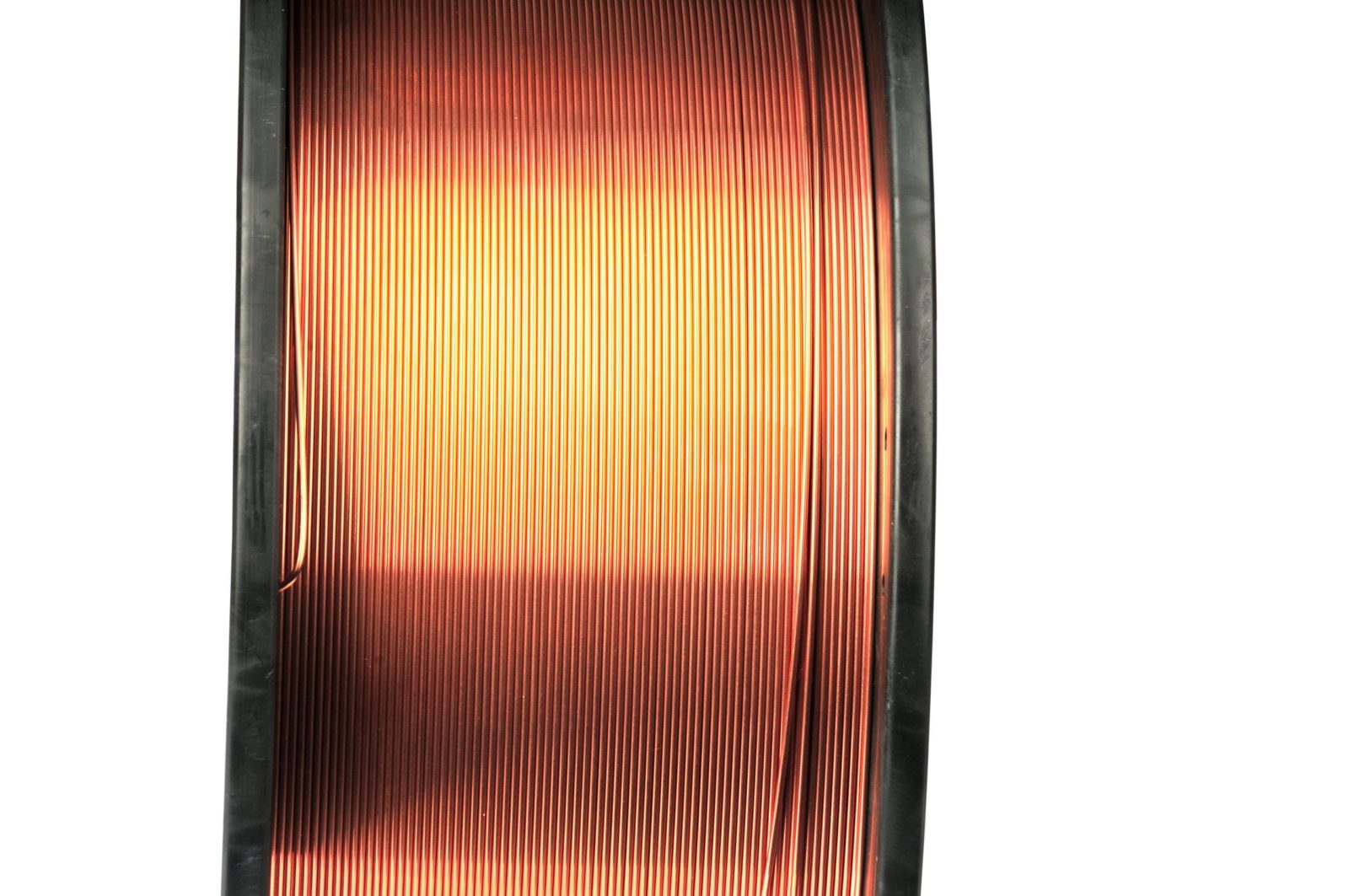

The main advantages of the welding wire are high-quality copper plating, stable diameter along the entire length, combined with a low content of harmful impurities, ensure stable combustion of the wire with minimal spatter and high quality of the deposited metal. In-line winding ensures smooth feeding of the welding wire into the welding zone, eliminating its deformation and bending.

Copper-plated welding wire ER70S-6 is used in shipbuilding, welding of metal structures, mechanical engineering.